Processing methods: Injection

Features: Low compression set, excellent oil resistance, heat resistance and hydrolysis resistance, excellent abrasion resistance and low temperature flexibility

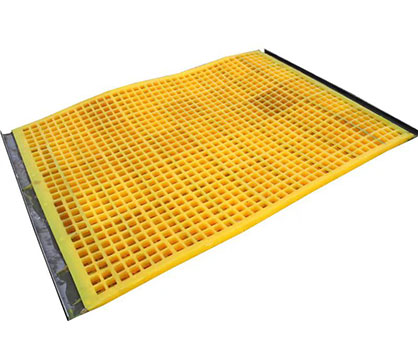

Applications: High-grade seals, elevator wheels, mine screens, cable sheathing, etc

| Properties | Standard | Unit | 2580 | 2585 | 2590 | 2595 |

|---|---|---|---|---|---|---|

| Density | ASTM D792 | g/cm³ | 1.17 | 1.18 | 1.18 | 1.19 |

| Hardness | ASTM D2240 | Shore A/D | 80 | 85 | 90 | 95 55 |

| Tensile Strength | ASTM D412 | MPa | 4 | 6 | 8 | 10 |

| 100% Modulus | ASTM D412 | MPa | 8 | 9 | 14 | 19 |

| 300% Modulus | ASTM D412 | MPa | 25 | 28 | 32 | 34 |

| Elongation at Break | ASTM D412 | % | 570 | 530 | 490 | 460 |

| Tear Strength | ASTM D624 | KN/m | 85 | 95 | 110 | 120 |

| DIN Abrasion Loss | 60 | 53 | 45 | 41 | ||

| Compression Set | 25℃/24h | % | 14 | 15 | 15 | 15 |

| 70℃/22h | % | 36 | 34 | 31 | 30 | |

| Tg | DSC | ℃ | 180-200 | 185-205 | 190-210 | 195-215 |

Note: The above values are shown as typical values and should not be used as specifications.